About Zirgy

[+]

export@shzjsmart.cn

Address

3F, Building 1, 875 Qiuxing Road, Pudong New District, Shanghai

RFID intelligent warehousing management system

Components of the system

|

|

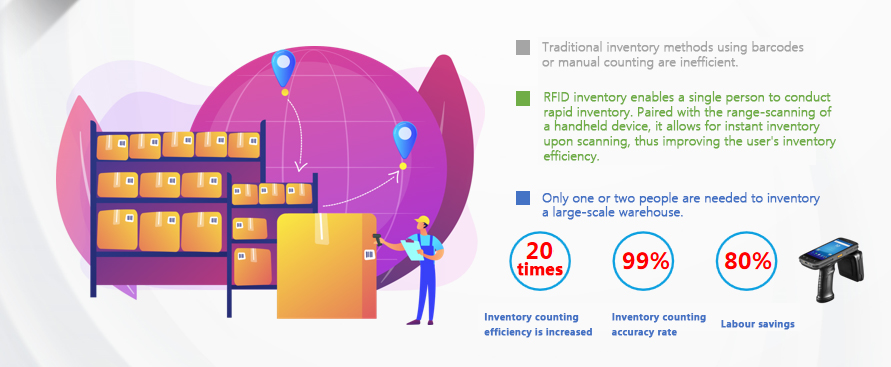

Handheld terminal Several handheld terminals, in accordance with the requirements of the system such as inbound and outbound operations and inventory taking, quickly scan the labels of goods and perform corresponding operations like inbound, outbound and inventory taking. They replace the traditional manual counting. Compared with scanning barcodes and QR codes, the scanning efficiency is increased severalfold.

|

|

|

|

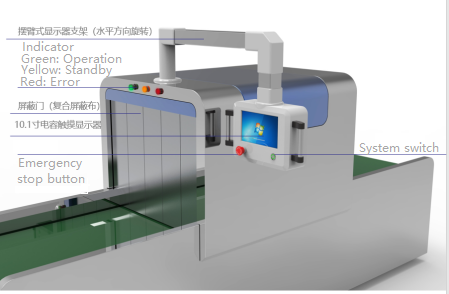

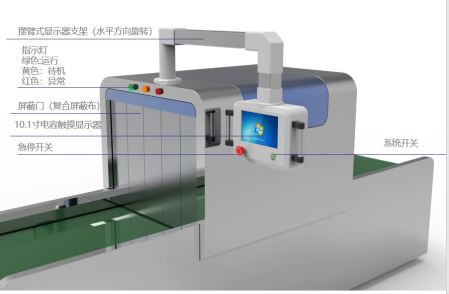

Interrogator/tunnel machine

They are all RFID scanning devices, and the difference lies in the different scanning accuracy and efficiency. The tunnel machine is more suitable for large-volume, effective and complex scanning situations. The hardware devices include: 1. Reader; 2. Tunnel machine.

|

|

Intelligent dashboard

The intelligent dashboard provides managers with the most intuitive and clear data visualization display. The intelligent dashboard can automatically update the data, and users can ensure the accuracy and real-time nature of the data by setting the automatic refresh time. The intelligent dashboard also supports data drilling. Users can click on the data points in the charts or graphs to view more detailed data, so as to have a deeper understanding of the data and information.

|

|

PC backstage management

If necessary, it can be integrated with the ERP system to obtain essential business information, such as inbound document information, outbound document information, inventory task information, etc. Secondly, it is also possible to view the corresponding operation records and product traceability information, such as inbound records, outbound records, inventory records, goods in stock, and so on.

|

Automatic binding of RFID tags

1. Confirmation of label requirements The system automatically confirms the quantity of labels required according to the quantity and specification requirements of the inbound order.

Scan while inventorying (using a handheld device) for quick inbound/outbound operations.

(Tunnel Machine) Quick Inbound/Outbound

The warehouse staff selects the inbound or outbound document through the industrial computer;

The tunnel machine conducts scanning;

Compared with the traditional inbound operation by scanning QR codes or barcodes, the RFID inbound operation can improve the efficiency by at least three times.

Automatic and Non-intrusive Quick Initial Inbound and Outbound

| Inbound: When the warehouse manager performs the inbound operation, he/she can carry out a non-intrusive inbound operation by simply walking through according to the business needs, or conduct a quick scanning inbound operation as required by the inbound document. Outbound: When the warehouse manager conducts the outbound operation, he/she can check the goods to be dispatched according to the outbound document, conduct a quick scanning and verification, and the system will prompt whether the goods can be dispatched.

Inbound and Outbound Process:

The warehouse staff selects the inbound/outbound document through the industrial computer. The system provides the location information of the goods that meet the inbound/outbound standards in the document. The warehouse staff scans the required quantity of goods as required by the document. The inbound/outbound operation is completed. Compared with the traditional inbound operation by scanning QR codes or barcodes, the efficiency of RFID inbound operation is at least three times higher.

|

|

Inbound and Outbound Operations with Forklift Transformation

Inbound and Outbound Process:

The warehouse staff selects the inbound task through the industrial computer;

Store the specified goods at the corresponding location as instructed in the document.

The warehouse staff selects the outbound task through the industrial computer;

Retrieve the specified goods from the corresponding location as instructed in the document.

Quick and Effective Inventory Taking

Standardization of operational requirements

It is possible to set the operation time rules for inbound requirements.

According to the actual business scenarios, pre-establish time requirement rules for inbound operations at different levels. When issuing tasks, it is optional to choose whether to follow the rules, and summarize and display the statistical results.

It is possible to set the operation time rules for outbound requirements.

According to the actual business scenarios, pre-establish time requirement rules for outbound operations at different levels. When issuing tasks, it is optional to choose whether to follow the rules, and summarize and display the statistical results.

It is possible to set the operation time rules for inventory taking requirements.

According to the actual business scenarios, pre-establish time requirement rules for inventory taking operations at different levels. When issuing tasks, it is optional to choose whether to follow the rules, and summarize and display the statistical results.

Visualization of operational efficiency

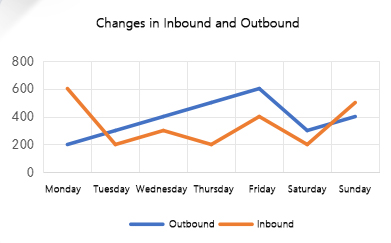

Line chart of inbound and outbound quantities

Show the changes in the quantities of inbound and outbound goods within a specific time period.

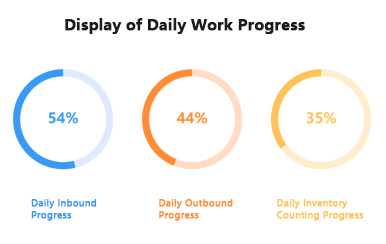

Daily inbound/outbound progress

Show the progress of daily inbound and outbound operations.

Uncompleted Inbound/Outbound Documents

Show the changes in the quantities of inbound and outbound goods within a specific time period.

Month-on-month Increase or Decrease in Inbound/Outbound Quantities This Month

Show the increase or decrease in the quantities of inbound and outbound goods this month compared with last month.

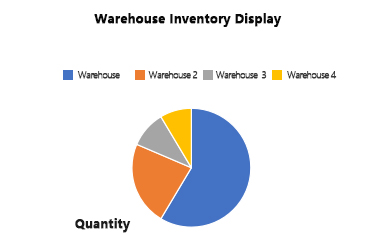

Warehouse inventory display

Show the inventory quantities of each warehouse.

Alarm for uncompleted tasks on time

Display the inbound and outbound contents that have not been completed according to the time rule requirements.

Real-time supervision on the operation big screen-Visual reports effectively display the work progress

|

|

[Changes in Outbound Quantity]

It can display the changes in the quantities of goods for both outbound and inbound operations in the warehouse within a certain period of time, and can comprehensively show the trend of benefit changes in the recent period. |

|

|

|

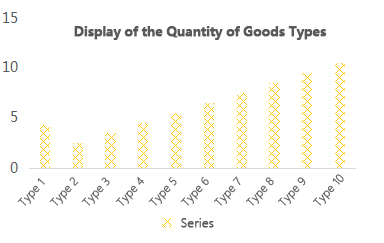

[Display of the Quantity of Goods Types]

It can display the stored quantities of all goods types in a specific warehouse, enabling a macroscopic understanding of whether there is any bias in the current warehouse's goods procurement direction, and thus facilitating the subsequent strategic adjustments. |

|

[Warehouse Inventory Display]

It can display the real-time proportion of inventory quantities in different warehouses, enabling you to quickly grasp the changes in the remaining inventory and plan the usage direction of the inventory in advance. |

|

[Display of Daily Work Progress]

It can display the tasks of outbound, inbound and inventory taking that need to be completed on that day in the form of percentage progress, enabling managers to quickly understand the progress of these tasks. |

Automatic alarm for overtime-Visual reports specifically display work tasks

|

|

[Overdue Outbound Records]

It can display the content of the outbound documents for which the tasks have not been completed on time, and show the corresponding overdue time. This facilitates on-site personnel to quickly understand the overdue situation and make reasonable responses. |

|

|

|

[Inbound Documents Pending] It can display the data of the documents that need to be processed for inbound in the future. And for the documents that need to be completed within the specified time, there will be a "Remaining Time" label behind them to remind the on-site personnel to make reasonable arrangements for the work schedule. |

|

[Overdue Inbound Records]

It can display the content of the inbound documents for which the tasks have not been completed on time, and show the corresponding overdue time, which enables the on-site personnel to quickly understand the overdue situation and make reasonable responses. |

|

[Outbound Documents Pending]

It can display the data of the documents that need to be processed for outbound in the future. For the documents that need to be completed within the specified time, there will be a "Remaining Time" note attached to them to remind the on-site personnel to make reasonable scheduling arrangements. |

Instant data aggregation improves productivity.

| 1 |

Alarm for overdue tasks. Check the reasons in a timely manner. |

2 |

The data on the large screen is displayed in real time, which saves time and reduces the error in information transmission. |

3 | Screen important data to increase the efficiency of viewing. |

| 4 |

Comprehensive display of warehouse information and operation progress |

5 | Control the overall task progress and allocate tasks reasonably. | 6 | Update the data comparison and provide accurate conditions for auxiliary judgment. |

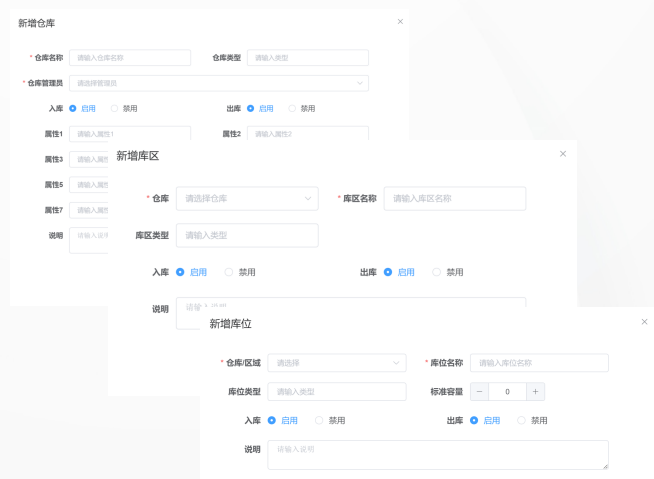

Unified management of warehouses, storage areas and storage locations.

|

It is possible to create the information of a three-layer structure consisting of warehouses, storage areas, and storage locations.

The operations of outbound, inbound, and inventory taking can all be carried out with meticulous attention to the storage locations.

1.For inbound operations, goods are required to be placed in specific storage locations.

2.For outbound operations, goods are required to be picked from specific storage locations.

3.For inventory taking, the inventory requirements for warehouses, storage areas, and storage locations can be added.

|

|

|

It can be integrated with other systems to improve the efficiency of the supply chain.

| The system can be seamlessly integrated with other peripheral systems such as mainstream ERP, SAP, OMS, TMS, financial systems, etc., to improve the efficiency of the supply chain. |

|

|

Supporting Hardware - RFID Electronic Tags (Multiple types of full-size tags are available for selection)

|

|

[Copperplate Paper/PET Electronic Tags] . Capable of printing and writing data.

. Optional chips include ZJXP01, ZJXP02, U8, U9, etc.

. The reading distance can reach up to 20 meters.

. Suitable for non-metallic or liquid materials such as paper, plastic, wood, glass, etc.

|

|

|

|

[Hanging RFID Tags] . Made of copperplate paper material.

. Capable of printing and writing data.

. Optional chips include ZJXP01, ZJXP02, U8, U9, etc.

. The reading distance can reach up to 20 meters.

. Suitable for hanging on items such as clothing, packaging bags, boxes, etc.

|

|

[Flexible Metal-resistant Tag] . Made of PET material with a thickness of 1.26mm.

. Capable of printing text, logos, and barcodes.

. Optional chips include ZJXP01, ZJXP02, U8, U9, etc.

. The maximum reading distance can reach up to 20 meters.

. Suitable for metallic materials.

|

|

[Metal-resistant Tag] . With a thickness of 7mm.

. Suitable for metal surfaces.

. Installation methods include screws, adhesive backing, and zip ties.

. Chips such as NXP UCODE 8, etc.

. The reading distance (by a handheld device) can reach up to 5.5 meters.

. The reading distance (by a fixed device) can reach up to 11 meters.

. The protection against water and dust is IP68.

|

Supporting Hardware-RFID Ultra High Frequency Handheld Terminal ZJ5020

|

|

Performance parameters

|

Supporting hardware-Long-distance RFID ultra-high frequency handheld terminal (imported impinj E710) ZJ5019RI

|

|

Performance parameters

|

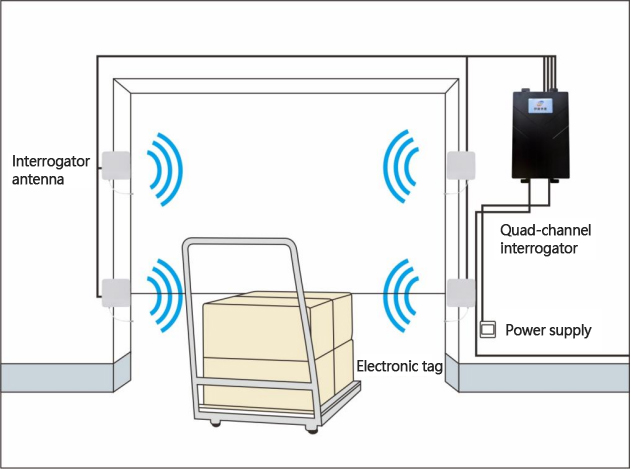

Supporting hardware-Ultra-high frequency four-channel interrogator ZJF001-4A

|

|

Performance parameters

|

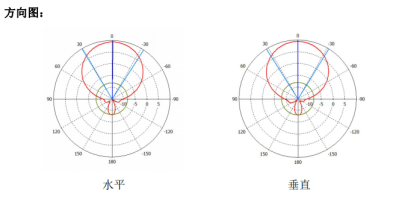

Supporting hardware-902-928MHz 8dBi RFID directional antenna ZJTX26026045-8DBI

|

|

Performance parameters

|

Supporting Hardware-RFID Tunnel Machine ZJTD003

|

|

Performance parameters

|

Applicable industry

|

|

|

|

|

|

|

|

|

|