About Zirgy

[+]

export@shzjsmart.cn

Address

3F, Building 1, 875 Qiuxing Road, Pudong New District, Shanghai

|

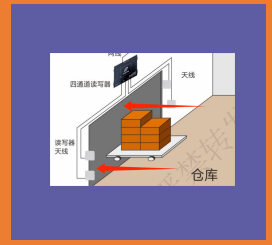

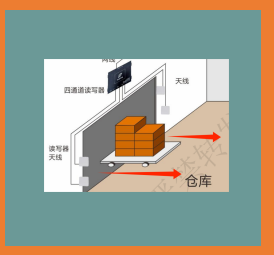

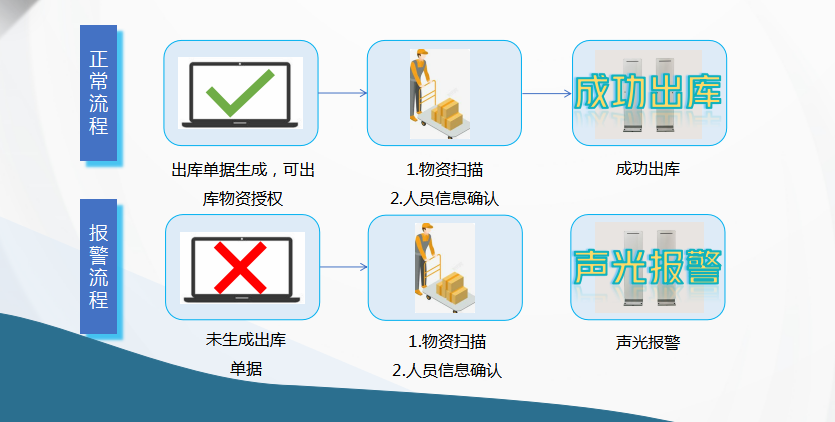

Reader/access door It is placed at the door to monitor the goods. When the goods that have not been sent out are exported and read by the reader, it will be considered that the goods are taken away maliciously. The optional hardware devices are: 1. Access door 2. Integrated machine

|

|

Intelligent kanban Smart Kanban is the most intuitive and clear visual display of data for managers. Smart Kanban can automatically update data, and users can ensure the accuracy and real-time of data by setting the automatic refresh time. Smart Kanban also supports data drilling, allowing users to get a deeper understanding of data and information by clicking on data points in a chart or graph to view more detailed data.

|

|

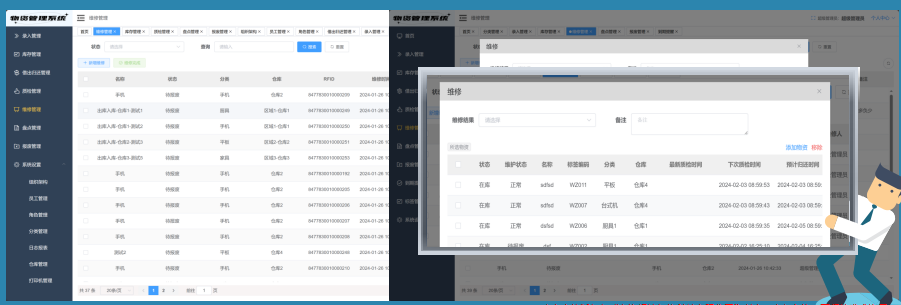

PC background management If necessary, it can connect with the ERP system to obtain the necessary business information, such as warehousing document information, warehousing document information, inventory task information, etc. Secondly, it can also view the corresponding operation records and goods traceability, such as warehousing record, warehousing record, inventory record, inventory goods and so on |

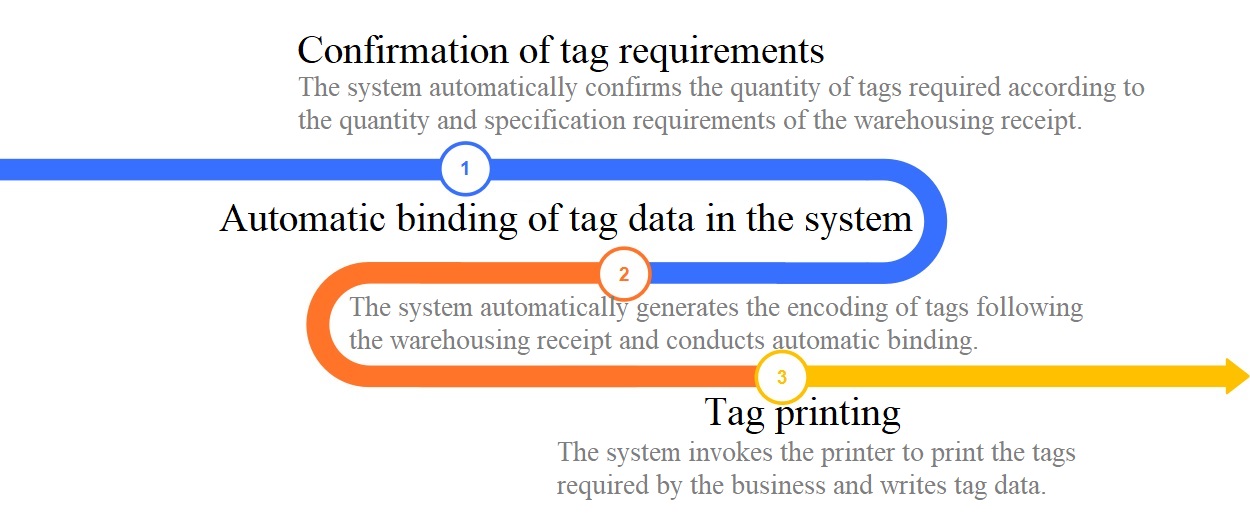

RFID tags are automatically bound

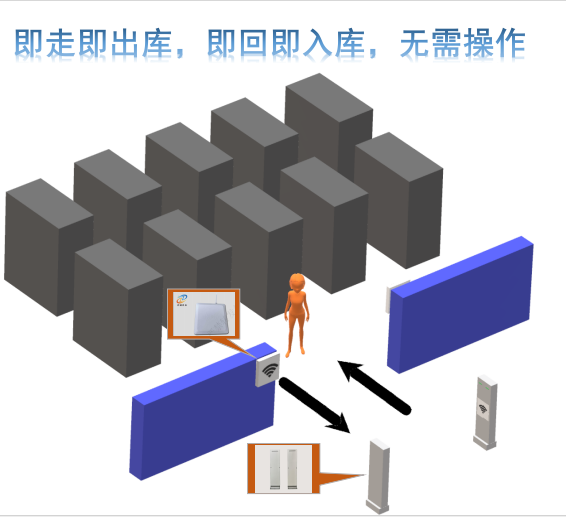

Free loan and return, no sensory scanning

|

When the warehouse manager goes to the warehouse to take the materials and leave the warehouse, the system will cooperate with the "remote UHF reader" on site to automatically identify the materials that are taken out of the warehouse as leaving the warehouse.

When the warehouse manager brings the outside materials back to the warehouse, the system automatically identifies the materials as incoming. The whole process has no sense of operation, convenient entry and exit. "Uhf RFID channel door" can be placed in the end of the warehouse defense line, as an illegal alarm warning assistant, when materials are taken out without authorization, the channel door will issue a sound and light alarm prompt, and upload the data to the system. |

|

Loan/return process

|

|

|

|

|

||

|

Personnel carry materials through the sensing area for exit scanning

|

|

Personnel carry materials through the sensing area for warehousing scanning

|

|

Personnel for information recognition confirmation (face recognition or work badge or RFID bracelet, etc.) |

|

Quick scan of equipment, warehouse entry/exit completed

|

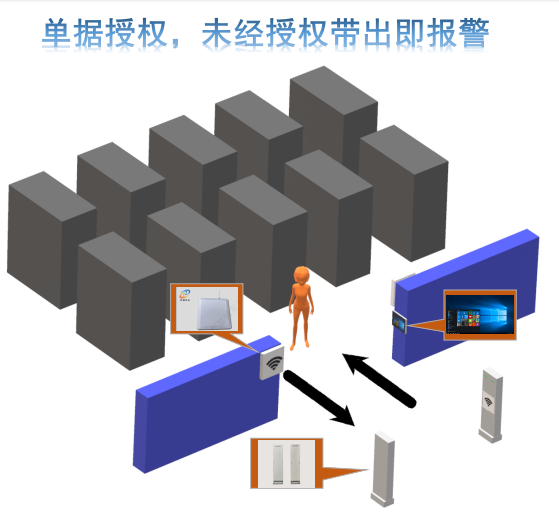

Document authorization allows lending

| 1. Generate loan (outbound) documents 2. When the warehouse manager goes to the warehouse to pick up the materials, select the exit documents from the operation screen, and leave the warehouse, the reader scans the label and retrives the documents. If there is no document authorization, sound and light alarm will be issued when passing through the passageway door. |

|

|

Monitoring abnormal alarm

Monitor important assets, take them out illegally and call the police

Quick and effective inventory

| Diverse ways, rigorous process ► The traditional bar code or manual counting method of inventory is inefficient

► Just one or two people can take inventory of large warehouses  |

|

|

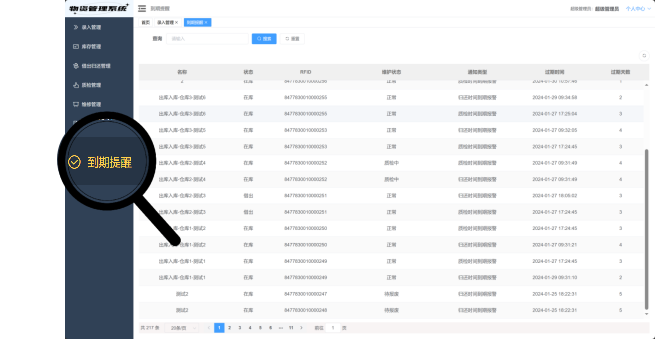

Quality inspection, return due reminder

|

1. For the loaned materials that have not been returned beyond the return time, the expiration reminder is carried out in the system. |

Unified inspection of overdue materials

|

|

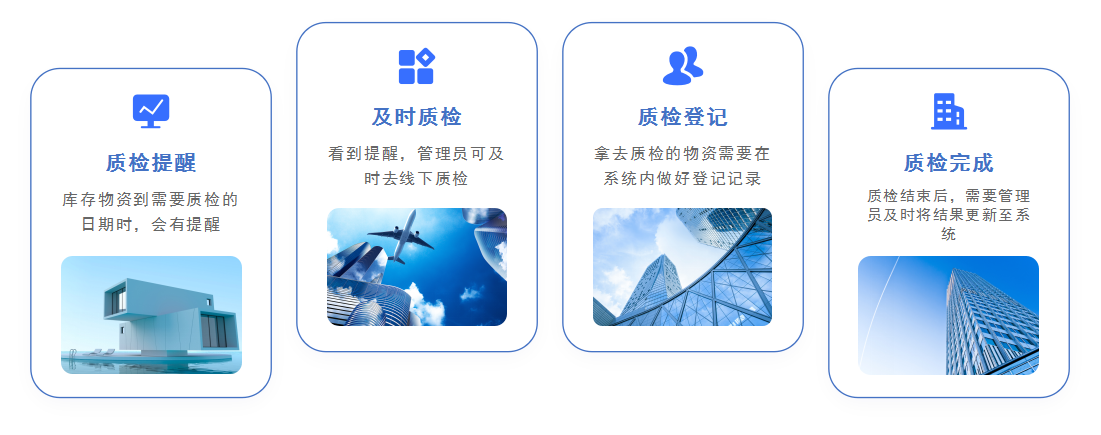

2. For the materials that need to be inspected but have not been inspected by the inspection date, send an expiration reminder in the system. |

||

|

3. Quickly understand the recent overdue situation of warehouse materials, which is conducive to control the management of warehouse operation quality. |

|

Timely quality inspection of materials

Timely maintenance of materials

Materials scrapping registration

Materials scrapping: Materials that need to be scrapped can be registered in the system for batch scrapping and scrapped with one click. The materials after scrapping are not used in the business of the system

Materials return: If there are inaccuracies or misoperations of discarded materials, the discarded materials can be restored to the system through restoration actions, and the materials restored to the system continue to participate in the business process of the system.

Job efficiency visualization

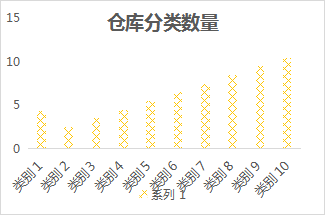

Warehouse inventory classification overview

Display different categories of inventory under each warehouse

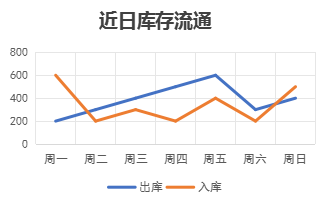

Recent inventory flow changes

Display the number of inbound and outbound storage trends in the time segment

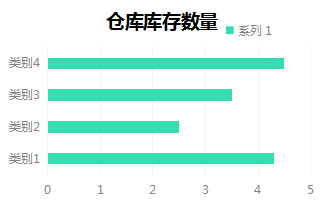

Total stock in warehouse

Show the total inventory of each warehouse

Loan (out) records

Show the loan record

Return (storage) records

Show return record

Alarm history

Display record information

Job screen real-time supervision

|

Visual reports effectively show work progress

|

Real-time data aggregation increases productivity

|

Filter important data to increase viewing efficiency

Control the overall task schedule and assign tasks reasonably

Real-time display of large screen data saves time and reduces information transmission errors

Comprehensive display of warehouse information and operation records Data comparison provides accurate auxiliary judgment conditions |

|

Interconnect with other systems to improve supply chain efficiency

The system can be seamlessly integrated with mainstream ERP, SAP, OMS, TMS, financial system and other peripheral systems to improve supply chain efficiency

Applicable industry

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

|

|