About Zirgy

[+]

export@shzjsmart.cn

Address

3F, Building 1, 875 Qiuxing Road, Pudong New District, Shanghai

Electronic lead-seal management system

Outstanding advantages of RFID

|

|

Large data storage capacity Two-dimensional barcodes can store at most 2,725 digits. If they contain letters, the storage capacity will be even less. In contrast, the storage capacity of an RFID tag is more than 2 to the 94th power (nearly ten thousand characters).

|

|

|

|

Convenient reading The data can be read without a light source, and it can even be read through the outer packaging. For passive tags, the furthest long-distance reading and writing distance can reach up to 1.5 meters. When using active tags with built-in batteries, the effective identification distance can exceed 30 meters. |

|

Fast reading and writing speed It adopts a contactless method and has no directional requirements. Once the tag enters the magnetic field, the reader can immediately read the information in it. Usually, one read-write operation can be completed within a few milliseconds. The anti-collision mechanism adopted enables it to process multiple tags simultaneously, achieving batch identification. |

|

Anti-collision There is a fast anti-collision mechanism in the electronic tag, which can prevent data interference between cards. Therefore, the reader can process multiple contactless RFID cards "simultaneously", handling more than 200 cards at a time. It does not require a light source and can even read data through external materials. |

|||

|

High data security RFID adopts the internationally unified encoding system of electronic product codes. The unique 40-bit identification internal code, which is solidified in the chip before leaving the factory, is non-repetitive, and it cannot be copied or modified. This technology is very difficult to be counterfeited or invaded. |

|

Superior physical performance It can store both persistent data and non-persistent data. The information in the rewritable memory can be changed freely. The data can be updated dynamically and reused repeatedly (it can be erased and written 100,000 times and read infinitely). It has a long service life (10 years or 100,000 times of read and write operations), can withstand high and low temperatures, and is able to adapt to various working environments and conditions. |

Existing problems of barcode/QR code

Anticipated goals

|

|

Fully automatic intelligent sealing/unsealing It not only saves labor costs but also greatly improves efficiency.

|

|

|

|

Handheld terminal sealing/unsealing The investment in the equipment is not large. In addition to the supervision of the lead seals, it also has the management function for the transportation of vehicles and goods. It is aimed at the scenarios where automatic sealing/unsealing is not applicable in practical situations.

|

|

Smart anti-theft The EPC code in the RFID lead seal chip has global uniqueness and cannot be replicated. In this way, the lead seal cannot be replaced, ensuring the reliability of the sealing.

|

|

Smart notification In case of any abnormal situation during use, it can promptly prompt and alarm the relevant management personnel.

|

|||

|

Vehicle smart monitoring Each link can accurately record information such as the time, location, and specific operator.

|

|

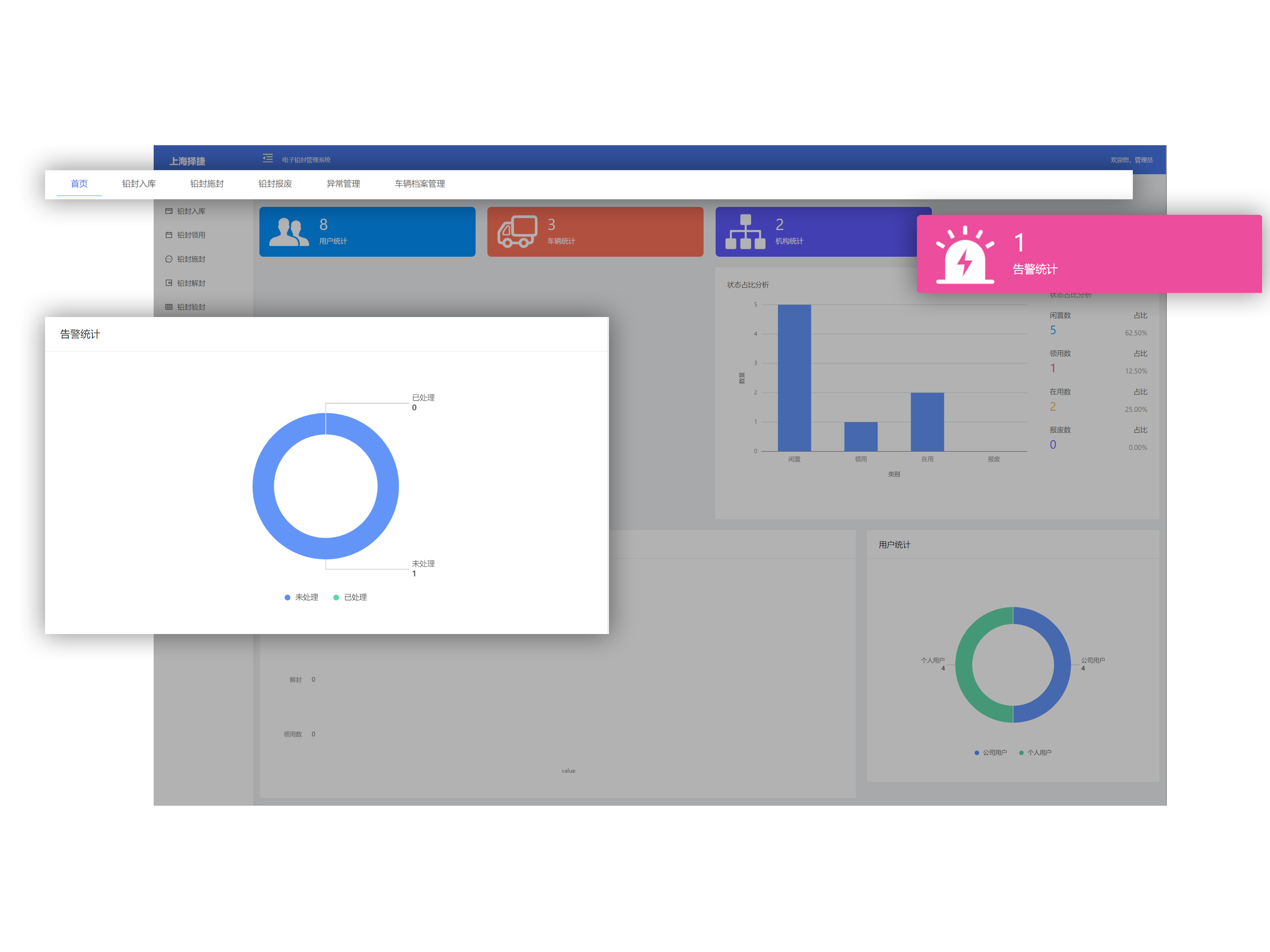

Customized permission management The management platform has a powerful query and statistics function, which is convenient for leaders to review. |

Benefits

| Reduce enterprise costs Personnel costs, time costs, consumable costs, etc. Reduce problems such as vehicles not following the specified routes. Improve efficiency, shorten operation time Comprehensively improve the operational efficiency of the processes from receiving materials to the sealing operation and the unsealing operation. Overtime work is eliminated, and there will be no delay in the departure of vehicles.

Reduce the error rate in operations, and lower the losses and negative impacts. Problems such as failure to seal, missealing, and incorrect sealing are reduced. The accuracy rate is improved through RFID technology, and the status of vehicles can be accurately grasped.

|

|

|

|

|

|

|

|

|

Paperless Labor force liberation

Electronic waybill

reduce manpower usage

|

|

Inventory monitoring Exception handling Inventory inquiry Verification upon exit and entry |

|

System automation Product visualization System invisibility Efficiency optimization |

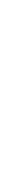

Full lifecycle management

|

Track every freight transportation behavior of the vehicle, provide a complete life cycle for viewing. For each specific vehicle unit, record information such as the operator, operation time, vehicle, and driver.

|

|

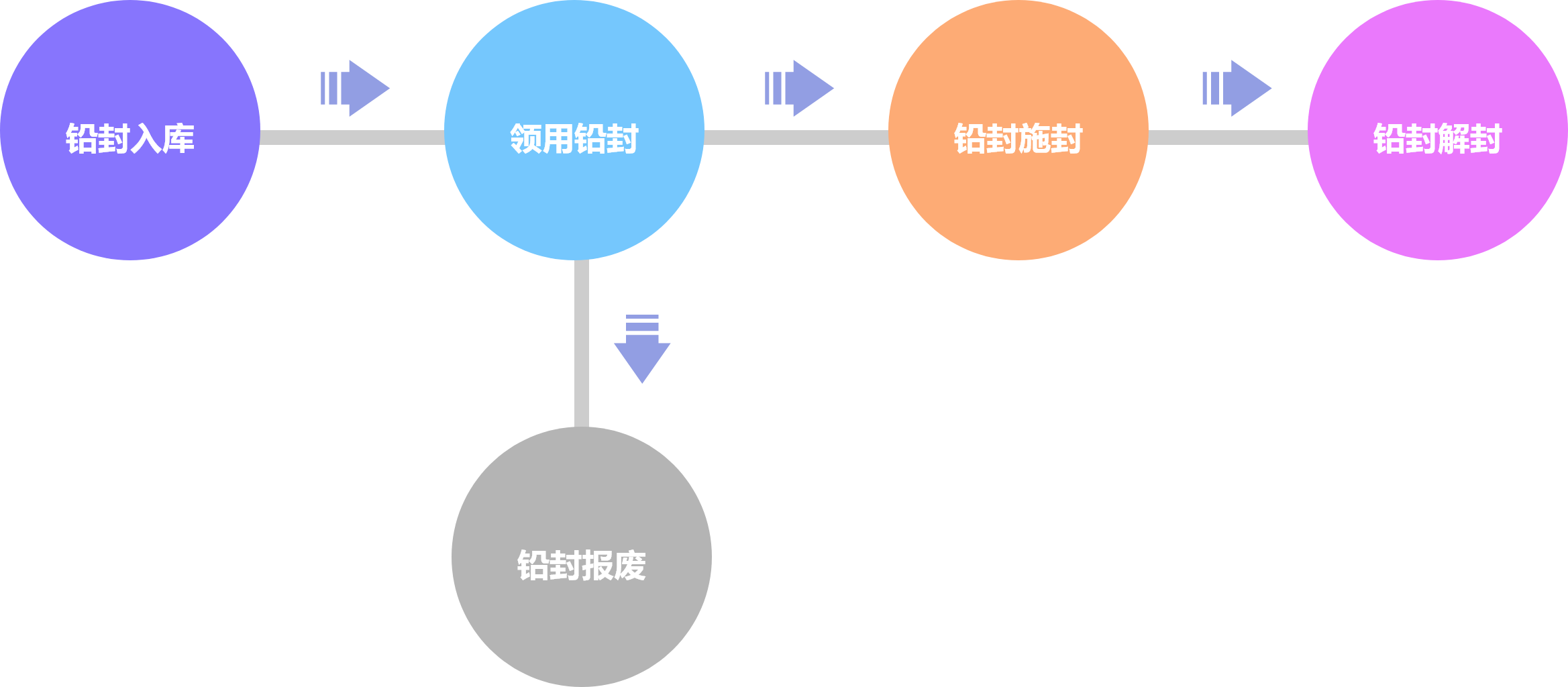

Smart batch warehousing of lead-seals

|

Batch import EPC code into excel The system supports batch import of lead seal EPC codes in the form of Excel spreadsheets to complete the warehousing process. You just need to fill in the EPC codes in the Excel template and then import them, which saves the time for warehousing and effectively improves work efficiency.

|

|

|

Smart single-item warehousing by RFID card issuer

| Quick scanning and warehousing with card issuers When a single lead seal needs to be warehoused, the system supports the warehousing operation through an RFID card issuer. After selecting the operator in the system, attach the lead seal to the RFID card issuer, and the system will automatically read the EPC code of the lead seal to complete the warehousing process.

|

|

|

Lead-seal smart collection

| Quickly collect items by scanning with the card issuer. After the administrator enters basic information such as the vehicle, driver, destination, and the person receiving the items, the RFID card issuer scans the lead seal label to complete the collection of the lead seal.

|

|

|

Fully automatic smart sealing

| Fully automatic seal application requires no human intervention. ✥ The camera in front of the vehicle automatically identifies the license plate information. ✥ An RFID reader-writer is installed at the sealing point to automatically identify the lead seal information and complete the sealing process. ✥ The camera at the rear of the vehicle automatically takes photos to ensure that the lead seal is intact and undamaged. ✥ The LED screen displays the sealing status and conducts voice broadcast. ✥ The sealing data is automatically uploaded to the cloud, and the system generates documents. ✥ There is no human intervention throughout the whole process, which is time-saving and highly efficient! |

|

|

Real-scene of the fully automatic smart sealing site

Handheld terminal manual sealing

| Manual scanning, dealing with the complex scenes During the sealing process, the operator uses a handheld device to scan the vehicle's lead seal. Based on the scanned information, the operator checks whether the vehicle information is correct. After the verification is completed, the sealing process is finalized.

The sealing operation with a handheld device involves human participation, making it more suitable for application scenarios with complex actual situations. With the involvement of personnel, the handling can be more proper. |

|

|

Fully automatic smart unsealing

| Fully automatic unsealing requires no human intervention. ✥ The camera in front of the vehicle automatically identifies the license plate information. ✥ An RFID reader-writer is installed at the unsealing point to automatically identify the lead seal information and complete the unsealing process. ✥ The camera at the rear of the vehicle automatically takes photos to ensure that the lead seal is intact and undamaged. ✥ The LED screen displays the unsealing status and gives a voice broadcast. ✥ The unsealing data is automatically uploaded to the cloud, and the system generates documents. ✥ There is no human intervention throughout the whole process, which is time-saving and highly efficient! |

|

|

Real-scene of the fully automatic smart unsealing site

Handheld terminal manual unsealing

| Manual scanning, handling complex scenes For scenarios where automatic unsealing is not applicable in practical situations, the system supports manual unsealing using a handheld device. Administrators can use the handheld device to scan the lead seal, verify the information, and check whether there is any cheating during the lead seal inspection process.

All the steps scanned by the all-in-one machine can be replaced by a handheld device, which can be used in conjunction with application scenarios that require human intervention to carry out unsealing and a series of operations. |

|

|

Smart anti-theft

| Effectively reduce theft When the vehicle arrives at the designated location for sealing/unsealing operations, if the lead seal does not match the one recorded in the system, resulting in the failure of sealing/unsealing, the system will not recognize it. This can surely detect the theft of goods and effectively restrains the malicious intentions of thieves.

When receiving the lead seals, the unique code of each label will be entered into the system by scanning the card issuer, so as to prevent the lead seals from being damaged and replaced halfway. |

|

|

Smart notification

| Smart notification, find problems timely When the system detects abnormal data, it will automatically issue a warning to remind the administrator, enabling the administrator to discover and handle the problem in a timely manner. This makes problem-solving more efficient and prevents problems from lingering and becoming difficult to deal with.

|

|

|

Multy-dimension statistical statement

| Analyze data, find the problems The system provides a variety of data statistical reports according to the actual needs of users. Corresponding conclusions can be drawn through the summarization of the data, which is convenient for analyzing the problems and making accurate decisions.

|

|

|