About Zirgy

[+]

export@shzjsmart.cn

Address

3F, Building 1, 875 Qiuxing Road, Pudong New District, Shanghai

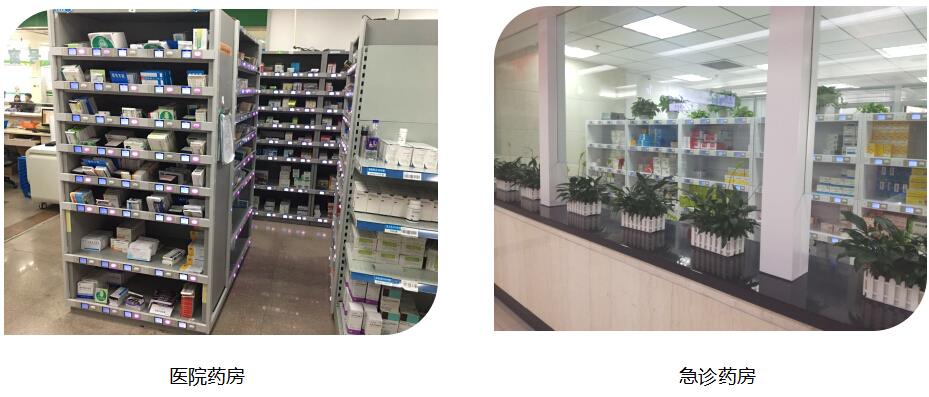

Digital picking system

Shanghai Zirgy's digital picking system is a warehouse picking auxiliary operation system developed using advanced electronic and communication technologies. It is typically used in the goods sorting process of modern logistics centers. By replacing picking lists with LED electronic tags installed on each storage location of the shelves, the system uses computer control to transmit order information to the electronic tags. This guides pickers to complete the picking work correctly, quickly, and easily. After finishing the picking, they can press the confirmation button to finalize the task. Moreover, it can be combined with devices such as voice systems, display boards, and alarm lights to form various extended applications.

System introduction

The Digital Picking System, abbreviated as DPS (also known as the PTL system, that is, the pick to light system). In the DPS system, for all the shelves in the picking operation area, an electronic tag is installed for each kind of goods/storage location. According to the data of the order list, it issues picking instructions and makes the electronic tags on the shelves light up (flash). The operator can timely, accurately and easily complete the commodity picking operation in units of "pieces" or "cartons" according to the quantity displayed on the electronic tag. The digital picking system can be extensively deployed in the picking and distribution operations of diverse industries, including e-commerce, tobacco, pharmaceuticals, daily necessities, electronic components, and auto parts.

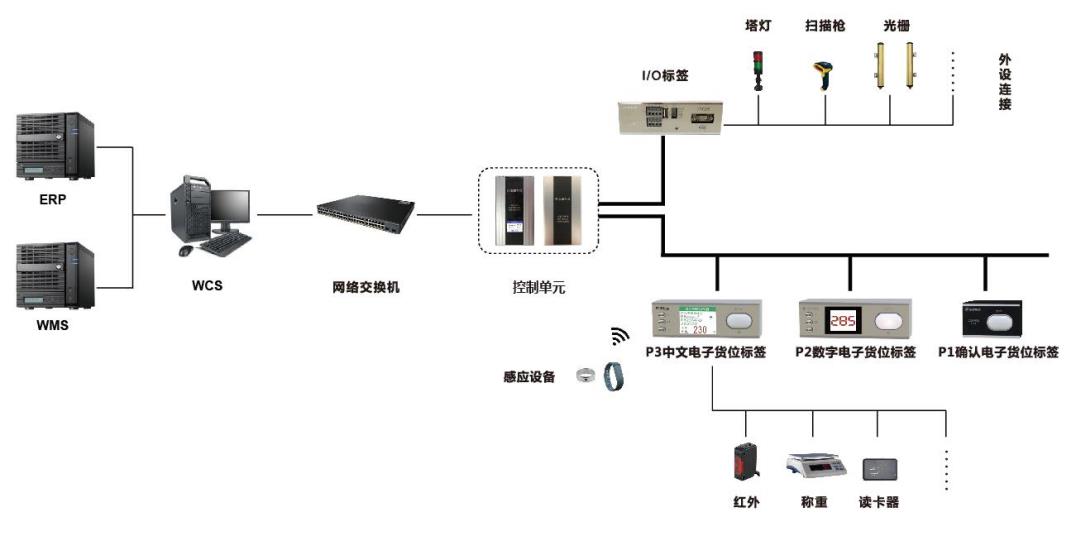

System Structure

Structure Instruction

● Data source: The inbound and outbound or order data is generated by the ERP system/WMS system;

● Control system: The WCS is used to download the corresponding documents from the ERP/WMS, and it can send and receive instructions to and from the control units;

● Network switch: It expands from one interface into multiple interfaces and is also known as a bridge;

● Control unit: It is composed of a regional power supply and a regional controller. It controls the operation of devices such as location tags and tower lights, and can transmit information back, enabling two-way communication;

● Location tag: It is used to display material information, inbound and outbound quantity information, etc., and can emit light indications.

● I/O tag: It can be connected to devices such as tower lights and barcode scanners.

● Control system: The WCS is used to download the corresponding documents from the ERP/WMS, and it can send and receive instructions to and from the control units;

● Network switch: It expands from one interface into multiple interfaces and is also known as a bridge;

● Control unit: It is composed of a regional power supply and a regional controller. It controls the operation of devices such as location tags and tower lights, and can transmit information back, enabling two-way communication;

● Location tag: It is used to display material information, inbound and outbound quantity information, etc., and can emit light indications.

● I/O tag: It can be connected to devices such as tower lights and barcode scanners.

Characteristics of Electronic Tag Picking System

Advantages of Electronic Tag Picking

● Using electronic location tags for picking can greatly accelerate the picking speed, improve the accuracy of picking, enhance the picking efficiency, and reduce the picking cost.

● It enables paperless operation, eliminating the need to print paper documents such as outbound slips and sorting lists. This reduces the time for document processing before outbound and saves paper.

● Using electronic tags for picking is simple and reliable in operation. Any person can start working after just a few minutes of simple training, which reduces the cost of personnel training.

● The picking control software can not only monitor the picking process in real time and record the picking status, but also provide real-time replenishment reminders, assist in the inventory taking operation, and can be integrated with other system platforms.

● By using Chinese electronic location tags, detailed information of goods can be displayed, including the product name, specification, location number, description, picking quantity, etc., so that the staff can view them accurately and intuitively.

● The CAN bus architecture is used to construct the picking production line. All devices are connected to the regional control line through the stable CAN bus for communication. The regional controller is connected to the management server via a local area network. The networking structure is simple, stable and reliable.

● It adopts the wired power supply and connection method (which is convenient for installation and disassembly and reliable), has industrial-grade stability. Sufficient power supply enables the tags to freely exert and expand their functions, making the practical application more efficient and enhancing the expandability of the product.

● This solution has a high level of maturity. The devices within the system have low power consumption and strong stability. The system can operate independently and does not rely on other systems. The design has fully taken into account the reliability and security of the network, host, operating system, database, etc.

● It enables paperless operation, eliminating the need to print paper documents such as outbound slips and sorting lists. This reduces the time for document processing before outbound and saves paper.

● Using electronic tags for picking is simple and reliable in operation. Any person can start working after just a few minutes of simple training, which reduces the cost of personnel training.

● The picking control software can not only monitor the picking process in real time and record the picking status, but also provide real-time replenishment reminders, assist in the inventory taking operation, and can be integrated with other system platforms.

● By using Chinese electronic location tags, detailed information of goods can be displayed, including the product name, specification, location number, description, picking quantity, etc., so that the staff can view them accurately and intuitively.

● The CAN bus architecture is used to construct the picking production line. All devices are connected to the regional control line through the stable CAN bus for communication. The regional controller is connected to the management server via a local area network. The networking structure is simple, stable and reliable.

● It adopts the wired power supply and connection method (which is convenient for installation and disassembly and reliable), has industrial-grade stability. Sufficient power supply enables the tags to freely exert and expand their functions, making the practical application more efficient and enhancing the expandability of the product.

● This solution has a high level of maturity. The devices within the system have low power consumption and strong stability. The system can operate independently and does not rely on other systems. The design has fully taken into account the reliability and security of the network, host, operating system, database, etc.

Main Benefits

● From the perspective of the system: After the system is completed, the supply chain and circulation processes will become smoother, the process time will be significantly shortened, and the whole-process control and management will be implemented for all aspects of the warehousing.

● From the perspective of management: It enables real-time control over aspects such as the storage location, batch number, shelf life, and distribution of goods, which is a crucial node for the refined management of enterprises.

● From the perspective of human resources management: Enterprises can manage and control their internal human resources more freely, and it significantly reduces the company's labor costs and employee training costs.

● From the perspective of work efficiency: It reduces the error rate during the commodity picking process and cuts down the corresponding working time. As a result, the company's production capacity is unleashed, and the company's annual compound growth rate is maintained at a relatively high level.

● From the perspective of management: It enables real-time control over aspects such as the storage location, batch number, shelf life, and distribution of goods, which is a crucial node for the refined management of enterprises.

● From the perspective of human resources management: Enterprises can manage and control their internal human resources more freely, and it significantly reduces the company's labor costs and employee training costs.

● From the perspective of work efficiency: It reduces the error rate during the commodity picking process and cuts down the corresponding working time. As a result, the company's production capacity is unleashed, and the company's annual compound growth rate is maintained at a relatively high level.

In comparison with traditional picking

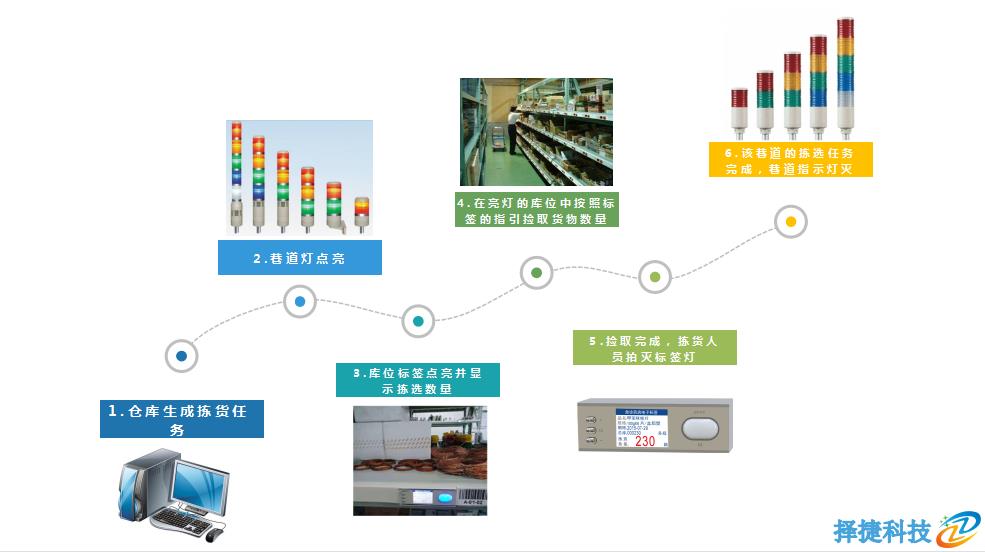

System Operating Procedure

System Function

1. Warehouse Inbound and Shelving: Create inbound tasks, carry out inbound operations, view inbound records, etc.

2. Picking and Outbound: Create picking tasks, conduct picking operations, check outbound records, etc.

3. Warehouse Inventory Checking: Create inventory tasks, conduct inventory operations, view inventory records, etc.

4. Inventory Management: Manage warehouse information, storage location information, inventory items and quantity information.

5. Personnel Management: It is used to manage and record system users and picking personnel, and establish simple personnel files.

6. Authority Management: Set different authorities for personnel. Only users with the corresponding authorities can view and modify the relevant information.

7. Early Warning Management: Provide early warnings and reminders regarding the upper and lower limits of the quantity of inventory materials, the shelf life of materials, etc.

8. Basic Information Configuration: Configure material types, names, specifications, etc.

2. Picking and Outbound: Create picking tasks, conduct picking operations, check outbound records, etc.

3. Warehouse Inventory Checking: Create inventory tasks, conduct inventory operations, view inventory records, etc.

4. Inventory Management: Manage warehouse information, storage location information, inventory items and quantity information.

5. Personnel Management: It is used to manage and record system users and picking personnel, and establish simple personnel files.

6. Authority Management: Set different authorities for personnel. Only users with the corresponding authorities can view and modify the relevant information.

7. Early Warning Management: Provide early warnings and reminders regarding the upper and lower limits of the quantity of inventory materials, the shelf life of materials, etc.

8. Basic Information Configuration: Configure material types, names, specifications, etc.

Electronic Goods Location Tag

|

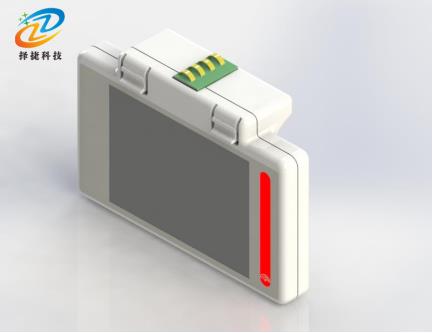

●ZJZ3L Electronic goods location tag

It has a 2.4-inch display screen and a seven-color confirmation light key. It can modify and transmit data back, and supports the display of numbers, English characters and Chinese characters. |

|

|

| ●ZJAE3 Electronic goods location tag It has a 2.4-inch display screen and features independent three-color light display. It supports the display of numbers, English characters and Chinese characters. |

|

|

| ●ZJZ320 Regional Direct Current Power Supply This is the power adapter for the entire label system. It has an input of 220V alternating current and an output of 24V direct current, providing power supply for the labels, controllers, and peripheral devices. |

|

|

| ●ZJZ630 CAN Zone Controller The zone controller is the core of the entire system for realizing electronic picking. It is connected to the host computer through the network port to receive data from the WMS/WCS system; and it sends the data of the WMS/WCS system to peripheral devices such as labels through the CAN bus to achieve the function of electronic picking. |

|

Industrial application