About Zirgy

[+]

export@shzjsmart.cn

Address

3F, Building 1, 875 Qiuxing Road, Pudong New District, Shanghai

Ⅰ Product introduction -- Strong acid and alkali resistant high temperature resistant metal label

Name: Strong acid and alkali resistant high temperature resistant metal label ZJ4631

Acid and alkali resistant high temperature resistant metal label ZJ4631 is designed and manufactured for use in harsh environments, it is installed on the surface of metal material, it can long-term resistance to 200 degrees of high temperature, long-term resistance to acid and alkaline environment, and can withstand ultrasonic cleaning. Strong acid and alkali resistance high temperature resistance and metal resistance label ZJ4631 Flexible installation, can be installed by rivet, or screw installation. In terms of reliability, this label can withstand: high temperature test, high and low temperature alternating test, acid and base test, vibration test, ultrasonic washing test. Strong acid, strong alkali, high temperature and metal resistance label ZJ4631 has been tested for performance consistency before leaving the factory, including the European label performance consistency comprehensive tester test, EPC and User area write test to confirm that the factory label has excellent reliability and performance consistency. It is suitable for automobile production line, high temperature metal pallet management in production line, storage shelf management, asset management, fixture and fixture management, university asset management, special vehicle management.

Acid and alkali resistant high temperature resistant metal label ZJ4631 is designed and manufactured for use in harsh environments, it is installed on the surface of metal material, it can long-term resistance to 200 degrees of high temperature, long-term resistance to acid and alkaline environment, and can withstand ultrasonic cleaning. Strong acid and alkali resistance high temperature resistance and metal resistance label ZJ4631 Flexible installation, can be installed by rivet, or screw installation. In terms of reliability, this label can withstand: high temperature test, high and low temperature alternating test, acid and base test, vibration test, ultrasonic washing test. Strong acid, strong alkali, high temperature and metal resistance label ZJ4631 has been tested for performance consistency before leaving the factory, including the European label performance consistency comprehensive tester test, EPC and User area write test to confirm that the factory label has excellent reliability and performance consistency. It is suitable for automobile production line, high temperature metal pallet management in production line, storage shelf management, asset management, fixture and fixture management, university asset management, special vehicle management.

Ⅱ Performance parameters -- strong acid and alkali resistance, high temperature resistance and metal resistance label

| Air interface protocol | EPC Class1 Gen2; ISO18000-6C |

| Operating frequency | 902-928MHz (US standard, compatible with national standard), 865~868MHz (European standard) (and other specific frequencies can be customized) |

| Chip type | Alien H3 chip (optional Impinj M4QT chip, or NXP Ucode 7M chip) |

| Chip storage | H3 chip: EPC 96bits (can be expanded to 480bits), user interval 512bits |

| TID | TID number is unique worldwide and cannot be modified |

| Read and write performance | Readable and writable (customers can write to the chip repeatedly) |

| Data preservation | 10 years |

| Quality warranty | 1 year |

| Product application surface materials | Applied to metal surface |

| Coating material | Gray-black engineering plastic |

| Product weight | 21 g/piece |

| Product form | Single |

| RoHS | Meet RoHS requirements |

| Product colour | Grey black (other colors can be customized) |

| Operating temperature | -25 degrees to 95 degrees |

| Long-term storage temperature | -45 degrees to 200 degrees |

| Peak temperature | 230 degrees @1 hour |

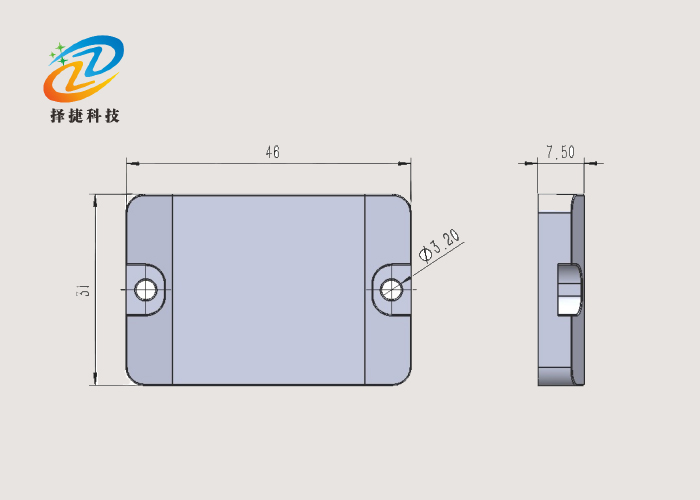

| Overall size (length * width * thickness) | 46mm * 31mm * 7.5mm |

| Through-hole diameter | 3.2mm |

| Through hole center spacing | 39.6mm |

Ⅲ Radio frequency performance - strong acid and alkali resistance to high temperature resistance to metal labels

| Stationary reader (on metal) | More than 6 meters (4W EIRP, using Alien9900 stationary reader, other readers, read distance may be different) |

| Handheld reader (on metal) | 2.5m or more (Read distance in outdoor open space using Alien9001 handheld reader, read distance may be different if other handheld devices are used) |

| Label polarization mode | Linear polarization |

| Functional and conformance testing | Full test and conformance test by Voyantic Finland |

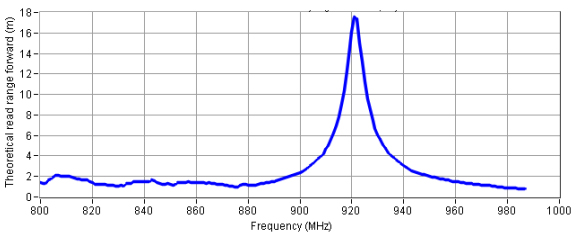

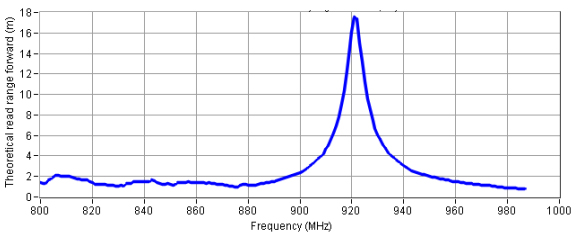

The following is the electrical performance test at each frequency (the test was tested by the Tagformace tag test system of Voyantic, Finland at 1OO%) :

Ⅳ Reliability test - strong acid and alkali resistant high temperature resistant metal label

Ⅳ Reliability test - strong acid and alkali resistant high temperature resistant metal label

| High temperature test | 200 degrees high temperature 180 days continuous test passed |

| Alcohol test | Passed the 95% sobriety test |

| Gasoline test | Gas 92 wipe through |

| High and low temperature alternating test | -40 degrees ~ 150 degrees 7 times high and low temperature alternating cycles, a total of 2 consecutive days through the test |

| RoHS | Passed, the material passed SGS certification |

| IP rating | IP68 |

| Ultrasonic cleaning test | Passed |

Ⅴ Optional - strong acid and alkali resistant high temperature resistant metal label

| Prewrite | Support |

| Laser surface typing | Support |

| Laser surface coding | Support |

| Surface screen printing | Supports surface monochrome or multi-color screen printing |

| Back with double-sided tape | Optional, but it does not support effective bonding at high temperatures above 100 degrees |

| Product appearance color customization | Support (5000 +) |

Ⅵ Installation mode -- Strong acid and alkali resistant high temperature resistant metal label

| Application purpose | High stability is required after installation, difficult to remove, and anti-vibration |

| Fit the occasion | Generally, it is used when the label is used for a long time and the label installation position is not changed |

| Rivet size | The diameter of the label through hole is 3.2mm, the diameter of the rivets used can be 3.0mm or 2.4mm, and the length of the rivets can be selected according to the actual needs (please also note that the rivets of different materials have different pulling forces, and their strength requirements for the structure are different, please test the structural strength of the label before use) |

| Delivery method | The rivets are non-standard and need to be purchased by the user |

● Screw mounting

| Application purpose | High stability and vibration resistance are required after installation |

| Fit the occasion | Generally, the label is used for a long time, but the installation position may need to be changed |

| Screw specification | The through hole diameter of the label is 3.2mm. The screw used is M3.0 or M2.5. The screw length can be selected based on actual requirements |

| Delivery method | The screws and nuts are non-standard and need to be purchased by the user |

| Remark | In the case of anti-vibration, it is necessary to add high temperature strong glue to the screw, or do other screw strong treatment that can withstand high temperature to prevent the nut from loosening |

Ⅶ Label placement - strong acid, strong alkali, high temperature resistance to metal labels

Whether the labels are correctly placed affects the read and write performance of the labels in some cases.

1) When the label is placed and installed, the following points need to be noted:

● The label needs to be installed on the metal surface, if the label is placed on the non-metal surface, the reading and writing performance of the label will be greatly weakened, even to the extent of seriously affecting the reading and writing of the label;

● There can be no metal barrier between the straight distance between the label and the reader antenna;

● The larger the metal surface at the bottom of the label, the better;

2) Polarization direction of the label:

1) When the label is placed and installed, the following points need to be noted:

● The label needs to be installed on the metal surface, if the label is placed on the non-metal surface, the reading and writing performance of the label will be greatly weakened, even to the extent of seriously affecting the reading and writing of the label;

● There can be no metal barrier between the straight distance between the label and the reader antenna;

● The larger the metal surface at the bottom of the label, the better;

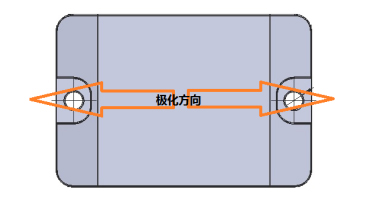

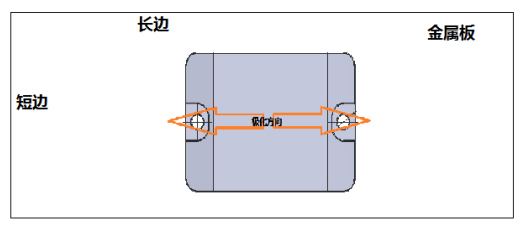

2) Polarization direction of the label:

Note the following three points for the polarization direction of the label:

● When the antenna of the reader is a standard circularly polarized antenna, the polarization matching of the label and the reader antenna can be ignored when the label is installed;

● When the antenna of the reader is a linearly polarized antenna, the polarization direction of the label must be consistent with the polarization direction of the reader antenna, otherwise it will not be able to read and write or the read and write performance is poor;

● When the installed metal surface is relatively small, the polarization direction of the label is better and the direction of the long side of the metal surface is consistent, and as far as possible in the center of the metal surface, as recommended in the following figure.

Ⅷ Product display -- Strong acid and alkali resistant high temperature resistant metal label

Real-shot display