About Zirgy

[+]

export@shzjsmart.cn

Address

3F, Building 1, 875 Qiuxing Road, Pudong New District, Shanghai

Ⅰ Product introduction

- This product features multi - protocol compatibility, a high reading rate, and a waterproof exterior design, meeting the requirements of harsh working environments.

- It fully supports electronic tags compliant with ISO - 18000 - 6C (EPC G2).

- It supports multiple communication methods such as USB, RS232, and Wiegand26/34.

- The output power can be adjusted up to 30 dBm, and it supports multiple working modes including timing mode, leader-follower mode, and trigger mode.

- It is suitable for applications in fields such as vehicle access control, non - stop automatic toll collection, personnel access control management, logistics monitoring, and production automation management.

Operating Frequency: Standard configuration with the option of ISM 902~928MHz or ISM 865~868MHz, other frequency bands can be customized.

Antenna Gain: Built-in circularly polarized antenna with a gain of 9dBi

Protocol: ISO18000-6C (EPC G2)

Development Kit: An SDK development kit is provided, and development routines for C#, VC, VB, Java, and Delphi are also offered.

Software: A test DEMO, as well as DEMOs for automatic card writing and reading, are provided to facilitate card issuing and writing for customers.

Output Power: 0~30dBm, adjustable via software

Communication Interfaces: Type N: Wiegand26/34, RS232/RS485, USB; Type E: Wiegand26/34, RS232/RS485, TCP, USB

Input Interface: 1 trigger input

Card Reading Mode: Automatic card reading at a fixed time and card reading controlled by external trigger, set by software

Card Reading Speed: Set by software, the average reading time for a single card is less than 6ms per 64bits

Reading Distance: 0-8m (high power: 0~10m) (The reading distance is related to the tag and the on-site environment)

Operating Temperature: -40℃~+65℃

Storage Temperature: -45℃~+95℃

Power Requirements: DC12V, 3A

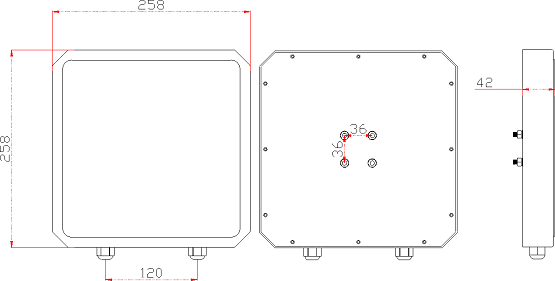

Dimensions: 257mm×257mm×42mm

Weight: 1.45 Kg (2.45kg with packaging)

Ⅲ Structure Dimensions of the Reader-Writer

Unit: mm

Ⅳ Purpose of the Reader-Writer

It can be used for item identification and data collection. Taking advantage of its excellent characteristics, it can be widely used especially in the following fields:

Transportation Management: Management of road and railway transportation, container transportation management, etc.

Motor Vehicle Management: Monitoring and management of various motor vehicles by public security, transportation and other departments.

Road and Bridge Toll Collection: Due to the ability of this product to read tag data from a long distance at a high speed, road and bridge toll collection can be carried out without stopping.

Customs Clearance Management: Management of goods and vehicles for customs clearance and transit.

Warehousing and Logistics Management: Management of the flow of goods and warehousing, as well as the flow management of mails, parcels, air luggage, etc.

Parking Lot Management: Achieving automation of management and toll collection.

Access Control Management: Including the entry and exit management of vehicles and personnel.

Process Production Flow: Monitoring of components throughout the production process.

Ⅴ Main Functions of the Reader-Writer

Wake up the Tag: Only the awakened tag can communicate with the reader-writer, preventing interference from other tags outside the system and ensuring the reliability and accuracy of information exchange between the reader-writer and the tags in this system.

Read Tag Data: It can not only read the ID number of the tag but also the data stored in the specified tag storage area; it can not only read the data of a single tag but also the data of multiple tags within the antenna wave range at the same time.

Write Tag Data: Data can be written into the specified tag storage area.

It can be directly connected to control devices with a standard Wiegand26/34 interface without the need for development, making it easy to use.

It is connected to a controller or a PC through a standard communication interface for data communication and exchange; an SDK development kit is provided for users to further develop applications.

Precautions for Use:

The ZJ903 series reader-writer is generally connected to a computer through the RS232 data interface for data exchange. Since the ZJ903 series reader-writer can only perform read and write operations on electronic tags after receiving control commands from the controller, we will provide customers with an SDK development kit, and users can develop application software.

The operating temperature of the reader-writer is -40℃~+65℃. Therefore, when using this reader-writer in cold regions and seasons, it is necessary to turn it on 15 minutes in advance for preheating before formal use to ensure its normal operation.

It is recommended that during the test, there should be no object blocking within at least 30 meters in front of the reader-writer; when holding the card, please touch the two edges of the card with your fingers. Since this antenna is horizontally polarized, the card should be placed horizontally and directly facing the reader-writer during the test to ensure the card reading effect.

The Wiegand communication interface must be connected to the GND ground wire.

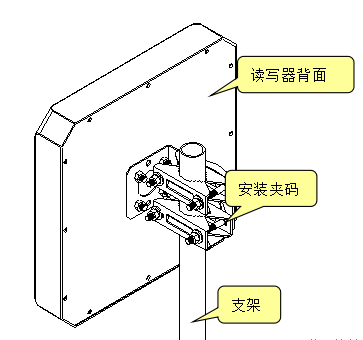

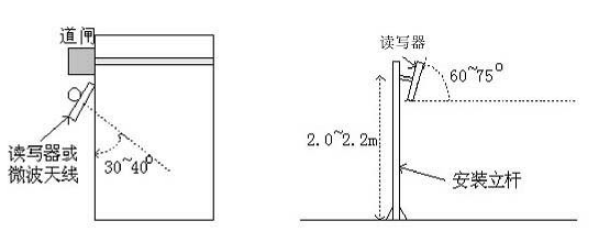

The installation height should be above 1.8M, and the diameter of the vertical pole is 40-60CM.

Ⅵ Working Mode and Wiring Instructions of the Reader-Writer

1. Wiring Instructions of the Reader-Writer

| Red | Black | Green | White | Grey | Purple |

| DC+(7-12V) | GND | RX | TX | WG-D1 | WG-D0 |

EPC GEN2 (ISO18000-6C) tags

Single Tag Initialization: Define the EPC length of the tag, generally 96 bits.

Single Tag Writing: Write to the EPC of the tag, and one address or multiple addresses (based on one address) can be written each time.

Single Tag Locking: Lock the EPC of the tag. After locking, the EPC of the tag cannot be rewritten.

Single Tag Destruction: Destroy the tag. After destruction, the tag can no longer be used.

3. Working Modes

Master-Slave Working Mode (COMMAND): In this working mode, the reader-writer works under the control of a PC or other controllers. The reader-writer and the control machine can communicate through one of the RS232, RS485 or Ethernet interfaces. This working mode supports all the functions provided by the secondary development kit.

Timing Working Mode (TIMING READ): The reader-writer automatically reads cards at a certain cycle (configurable), and the read data is output through the specified communication port. The operation on the tag in this mode is only for reading.

Trigger Working Mode (TRIGGER READ): When a low level is input to the trigger input port, the reader-writer starts to read cards periodically and will automatically turn off after a period of time.

4. Adjacent ID Discrimination

Adjacent ID discrimination is designed to reduce the redundancy of data uploaded by the reader-writer. When this function is selected, when the reader-writer reads the card number of the same tag continuously for multiple times, only one set of data will be uploaded within the set time. The effective time for adjacent discrimination can be selected, that is, if the time interval between two adjacent card readings exceeds the effective time, adjacent comparison and discrimination will not be carried out on them. Users should select it according to specific needs. It is commonly used in Wiegand communication.

Ⅶ Configuration of the Reader-Writer

Our company provides a DEMO software program for configuring the working parameters of the reader-writer. The parameter configuration program interface is shown in the following figure:

Ⅷ Installation of the Reader-Writer

1. Installation Methods of the Reader-Writer

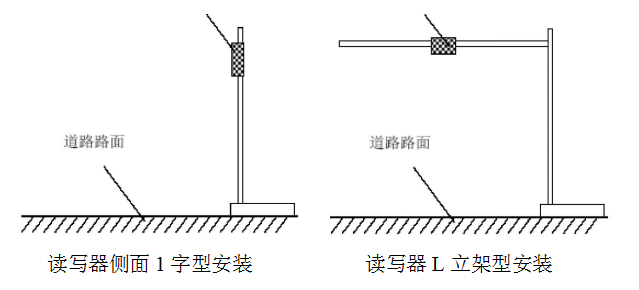

There are two installation methods for the vertical stand of the reader-writer: "Side 1-shaped installation" and "L-shaped vertical stand installation" as shown in the following figure: You can choose the installation method according to the application requirements and the actual on-site situation. Generally, the side installation has a shorter reading distance but is simple to install; the top installation has a longer reading distance but is more complex to install.

2. Fixing and Height Adjustment of the Reader-Writer

When installing the ZJ903-9DBI reader-writer on the side of the 1-shaped vertical stand, the diameter of the installation vertical pole should be 40~60mm and the length should be 2.2m. It is advisable to use stainless steel materials with a wall thickness greater than 1.2mm. Use the fasteners provided in the packaging box of the ZJ903-9DBI reader-writer to fix the reader-writer on the top of the vertical pole. Adjust the height from the center of the ZJ903-9DBI reader-writer to the horizontal plane of the lane according to the vehicle type (mainly referring to large and small vehicles), generally about 2.0m (1.8~2.2m).

When installing the ZJ903-9DBI reader-writer on the top of the L-shaped vertical stand, the diameter of the vertical pole (or gantry-shaped) of the L-shaped stand should be 60~80mm, and the diameter of the crossbar should be 40~60mm. It is advisable to use stainless steel materials with a wall thickness greater than 1.2~2.0mm. Similarly, use the fasteners provided in the packaging box to fix the ZJ903-9DBI reader-writer at a position on the crossbar close to the middle of the lane. Adjust the height of the crossbar from the ground between 3.5m~4.0m according to the height of the vehicle.

3. Adjustment of the Azimuth Angle of the Reader-Writer

Antenna Azimuth Angle: It refers to the offset angle of the antenna towards the lane direction, about 30~40°.

The principles for selecting the installation location of the ZJ903-9DBI reader-writer system are:

The straight-line distance between the ZJ903-9DBI reader-writer and the road gate should not exceed 1 meter.

There should be no object blocking between the location of the ZJ903-9DBI reader-writer and the tag card.

The distance between the ZJ903-9DBI reader-writer and the control device (or PC) should be as close as possible, and use a shielded communication cable as required. The specific on-site installation implementation is generally determined according to the on-site situation, which is explained as follows.

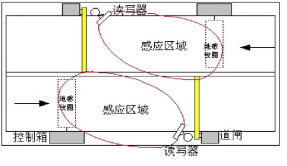

On-site Installation Method 1: There is no middle isolation safety island on the road, and the road control device (road gate) is installed on both sides of the road. Vehicles pass through the card reading area at a speed of less than 30 kilometers per hour.

In this case: It is required that the reader-writer (antenna) should be close to the road gate device, and at the same time, the effective range of its tag reading (the farthest straight-line distance is 0.5 meters~10 meters) should cover the entrance or exit ground induction coil, as shown in the figure:

On-site Installation Method 2: There is a middle isolation safety island on the road, and the control device (road gate) is installed on the middle isolation safety island. Vehicles pass through the card reading area at a speed of less than 10 kilometers per hour.

In this case: It is required that the ZJ903-9DBI reader-writer should be close to the road gate device, and at the same time, the effective range of its tag reading (the farthest straight-line distance is 0.5 meters~10 meters) should cover the entrance or exit ground induction coil, as shown in the figure:

Ⅸ Secondary Development of ZJ903-9DBI

Users can conduct secondary development of the application software of the reader-writer according to their needs. We provide calling routines for C#, VC, VB, Delphi, Java, etc., and also provide driver development for WINCE and LINUX. Please refer to the "SDK Development Guide" for the use of the development kit.

Ⅹ Product Display