About Zirgy

[+]

export@shzjsmart.cn

Address

3F, Building 1, 875 Qiuxing Road, Pudong New District, Shanghai

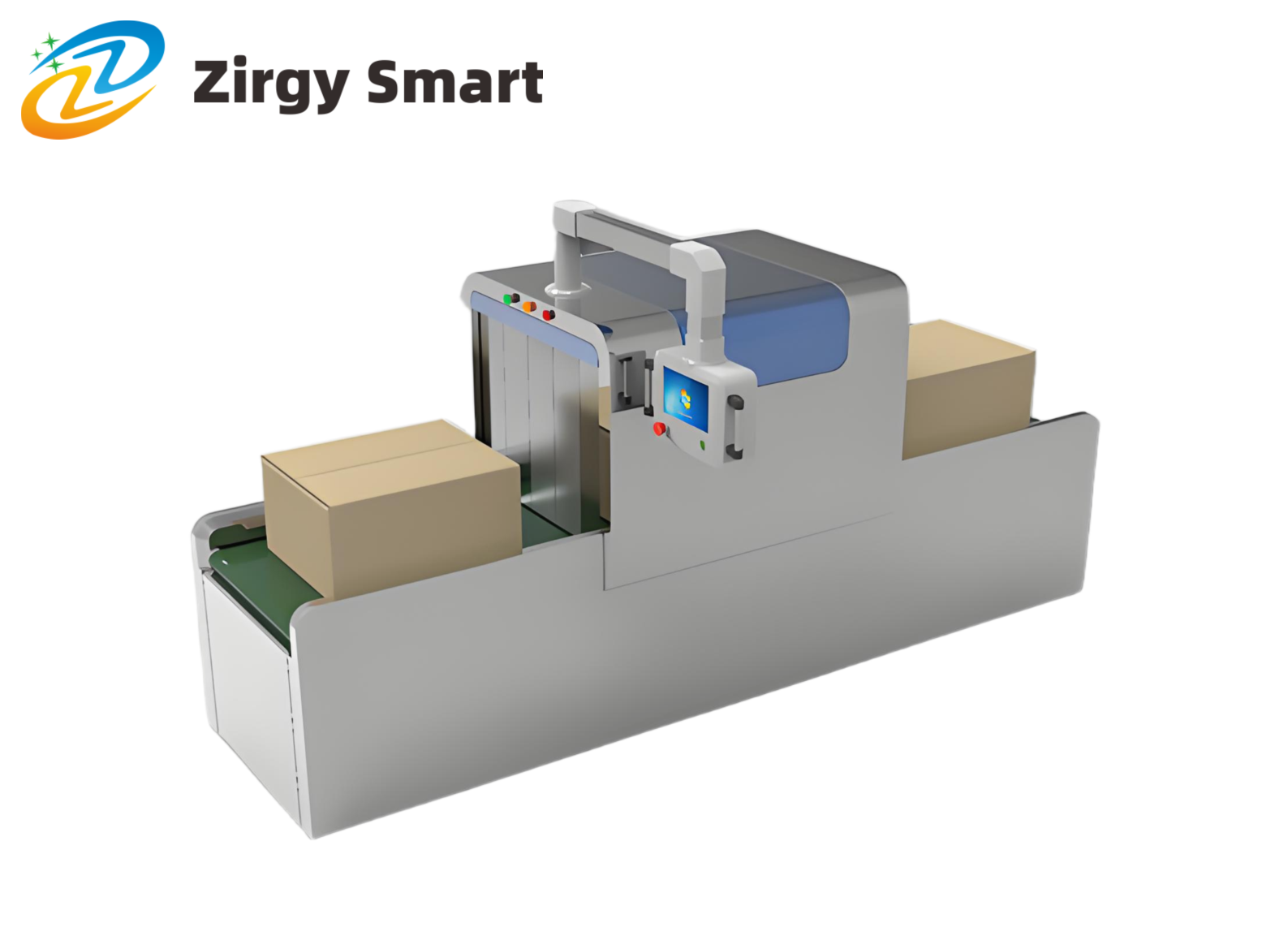

Ⅰ Product overview

1.1 Product introduction

The ZJTD03 RFID conveyor conducts operations such as inventory checking and rechecking by combining radio frequency identification (RFID) technology with a conveying channel. It can quickly identify multiple items in a batch of single boxes, saying goodbye to the backward traditional method of manual inventory counting. The equipment is integrated with various sensors and uses the control logic of Programmable Logic Controller (PLC) for automated identification. It has a fast identification speed and can identify more than 300 items within 3 seconds. Moreover, it can generate a real-time list on the display screen, conduct verification, and provide corresponding prompts and alarms, which is convenient for managers to check. This greatly saves manpower and time.

1.2 Operating environment

The ZJTD03 RFID conveyor should operate on a dry, hard and flat ground indoors, and it is required to have good ventilation and heat dissipation conditions.

Operating temperature: 0℃~50℃

Storage temperature: -10℃~60℃

Environment humidity: 10%RH~90%RH

Impact on environment and energy:

Any radio transmitting equipment, including this device, may potentially interfere with the operation of medical equipment that is not properly protected. If there are any issues in this regard, you can consult the manufacturer of the relevant medical equipment. The operation of this device may also cause interference to other electronic devices.

1.3 Safety and protection measures

- The equipment should be turned off in a timely manner when getting off work.

- After the installation is in place, it must be fixed, and it is necessary to ensure the equipment maintenance door can be opened normally.

- The keys on the equipment are prohibited from being left on the equipment. All access doors must maintain closed and locked when there is no maintenance work being carried out.

- Use the power switch on the equipment to turn off the equipment. Directly cutting off the power supply is prohibited.

2.1 Main features

- It supports the internationally popular ISO 18000-6C air interface protocol standard.

- The integrated design reduces equipment redundancy.

- It has the functions of EPC tag matching and duplicate tag filtering.

- Intensive reading mode.

- Windows10 operating system.

- It can work independently without being connected to the network.

- It supports the upgrading of both software and hardware.

- Operating frequency: 920-925MHz (Chinese standard)/902-928MHz (American standard)

- Operating standard: ISO 18000-6C/EPC C1G2 、 ISO 18000-6B、

- GB/T29768-2013 (It can be expanded for support)

- Output power: 33dbm/36dbm

- Conveying speed: up to 40m/min

- Transmission load-bearing: up to 80KG

- The number of tags read: more than 400 pieces at a time

- TOuch display screen: 10.1 inches

- Operating system: windows/Android

- Electrical control: Delta PLC is equipped with a closed-loop stepper motor.

- Conveyor line body: It is controlled independently in three sections, and the speed is adjustable.

Ⅲ Dimension and weight

3.1 Appearance and installation dimension

External dimension: 800 × 1800 ×1200 mm (length × width × height)

3.2 Weight

≥ 150 KG

Ⅳ Structural features and working principle

4.1 Overall structure

The ZJTD03 RFID conveyor is composed of parts such as antennas, a read-write module, a power supply module, an industrial control host computer, a touch display screen, a chassis shell, and other optional accessories.

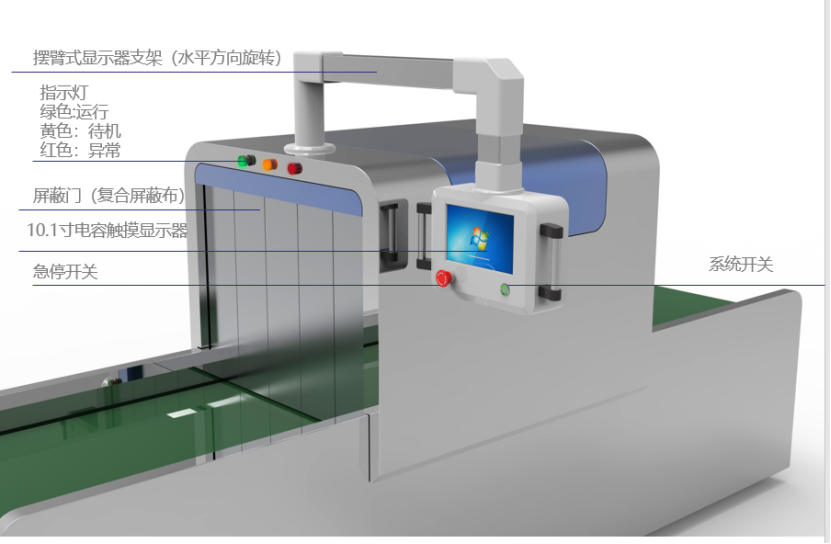

4.2 Structural description

As shown in the above figure, the external structure of the ZJTD03 RFID conveyor is in the form of a cabinet. There is a touch display screen on the top, and a scanning device platform and an induction indicator light in the middle.

4.3 Configuration list

| Serial number | Name | Unit | Amount | Standard configuration/ Optional configuration | Remarks |

| 1 | RFID conveyor | unit | 1 | Standard configuration | Main body casing, including the internal transmission mechanism. |

| 2 | Ultra-high frequency RFID components | set | 1 | Standard configuration | Including antennas and readers. |

| 3 |

Industrial control computer |

set |

1 |

Standard configuration |

It runs on Windows 10, with 2GB of RAM and 32GB of storage. Android system is optional. |

| 4 | Display screen | set | 1 | Standard configuration | 10.1-inch capacitive touch screen |

Ⅴ Installation and debugging

5.1 Installation precautions

In order to ensure the cleanliness of both the inside and outside of the equipment, dust-proof gloves must be worn during the installation of the equipment. Since the equipment is relatively large in size, it must be fixed in an open area during installation. At least, it is necessary to ensure that the top door, front door, and rear door can be smoothly and completely opened to facilitate the installation of the internal equipment.

Warning: For the safety of the equipment and personnel, the equipment must be installed and repaired when it is powered off. Working on live equipment is prohibited.

Note: The equipment must not be laid down or tilted at a large angle at any time. The protective layer on the touch display screen must not be removed before the equipment is delivered for use.

5.2 Installation conditions

The equipment needs to be installed in an open and bright environment where it can be easily moved to the actual installation location. During the installation process, the equipment must be fixed. After the installation is completed, it can be moved to the fixed position via the universal wheels under the equipment and then secured.

5.3 Test

Turn on the power switch and check whether the power indicator lights of each device are on. After confirming that the power supplies are all normal, turn on the industrial control host computer to detect the running status of the computer and configure the network.

Install the application software and conduct tests.

5.4 Acceptance

The acceptance of the ZJTD03 RFID conveyor mainly includes the structural acceptance and the performance acceptance.

5.4.1 Structural acceptance

Check whether the installation complies with the installation standards and whether the connections between various devices are normal.

- Whether each component is firmly fixed;

- Whether all components have been installed in place;

- Whether all kinds of cables are firmly connected and connected correctly;

- Whether the cables are arranged neatly;

- Whether the screws are tightened;

- Is there any hard damage to the appearance of the equipment?

- Whether each door can be smoothly opened and closed.

5.4.2 Performance acceptance

Check whether the equipment is working properly mainly from the following aspects:

- Check whether the equipment is working properly.

- Whether each function of the application software meets the requirements;

- Whether the reading and writing distance of the equipment meets the requirements.

Ⅵ Use instruction

6.1 Preparations and inspections before use

The following preparations and inspections need to be carried out before using the equipment:

- Check whether the equipment starts up normally.

- Whether the reading performance of the antenna meets the requirements;

- Whether the system parameter configuration meets the functional requirements.

Windows10 system, install .NET Framework 4.5.2

6.3 Software installation

Nil

6.4 Daily maintenance

- Wipe the outer shell: When the device is powered off, clean the touch screen with an LCD screen cleaning kit or a soft and clean cloth (such as an eyeglasses cleaning cloth), and wipe other parts with a clean cloth.

- If the equipment is to be out of use for an extended period, the main power supply of the equipment should be turned off, and dust-proof items should be placed over the equipment.

- Before resuming the use of the equipment after it has been out of use for a long time, you should first open the cabinet to inspect the connecting cables of the equipment. After ensuring that the connections are secure, turn on the main power supply and then start using the equipment.

- Store it in a cool and dry environment.

Power supply system failure

Check whether the power cord of the equipment is firmly connected and whether there is any damage.

Check whether the control switch on the power strip is turned on, whether the main unit switch is turned on, and whether the power indicator lights of each device are normal.

Unable to read the tag information.

Check whether all the connectors of the antenna are loose. If any are loose, tighten the loose parts.

Test with the "demo software" to determine whether the antenna number is incorrect.

Ⅶ Transportation and storage

7.1 Transportation requirements

- It is suitable for transportation modes such as railway, highway, aviation and waterway transportation.

- Packed in wooden cases with foam lining.

- It should be placed upright and must not be placed horizontally or upside down.

- Stacking is prohibited. Forklifts or wheeled vehicles should be used for handling.

- It is prohibited to place items weighing more than 20Kg on the packaging box.

- All components must be installed firmly, and there should be no severe vibration during the transportation process.

- When storing the equipment, cut off its power supply and cover it with a dust-proof cloth.

- It is prohibited to stack items on the upper part.

- The environmental requirements are a cool and dry place, and the temperature should not be higher than 30℃.

Ⅷ Unpacking and inspection

8.1 Packaging instructions

- Packed in wooden cases. The external dimensions of the packaging: 820 X 1820 X 1220mm.

- The markings of "This Side Up", "Fragile", "Keep Away from Moisture" and the identification of the stacking layers are printed on the side.

- The net weight, gross weight and production date of the equipment are printed on the front side.

- In order to facilitate future storage and transportation, please properly keep the packaging box and packaging materials after opening the package.

- When unpacking, first look for the "Packing List", and then check whether the equipment and accessories are complete according to the contents on the packing list.

- In addition to the product itself, the packaging box also includes the accessories required for the use of the product.

Ⅸ After-sales services and contact information

9.1 After-sales services

When users encounter problems that cannot be solved while using this product, please contact the customer service center of our company.

Before users contact the customer service center of our company, please have the users record the following information at hand:

- Product model and serial number;

- The manifestation of the product failure;

- Possible reasons of product failure.

Shanghai Zirgy Intelligent Technology Co., Ltd.

Address: 3rd floor, Building A, No. 875, Qiuxing Rd, Pudong New District, Shanghai

Postal code: 201306

Phone number: 400-868-5581

Website: http://www.shzjsmart.cn

Ⅹ Product display